Making the TFF Aerial

- St.John

- Tench

- Posts: 2760

- Joined: Thu Sep 01, 2011 3:25 pm

- 12

- Location: the monnow

- Loop Erimder

- Wild Carp

- Posts: 9984

- Joined: Wed Apr 04, 2012 11:33 pm

- 12

- Location: Leicestershire

Re: Making the TFF Aerial

That ebony makes it so unique great idea :thumb:

Chance is always powerful. Let your hook be always cast; in the pool where you least expect it, there will be a fish

- Nobby

- Wild Carp

- Posts: 10987

- Joined: Sun Oct 02, 2011 2:40 pm

- 12

- Location: S.W.Surrey

- Contact:

Re: Making the TFF Aerial

Do you know, had you not pointed it out, I'm not entirely sure I'd have spotted the split, if I'm honest.

It really isn't that obvious.

It really isn't that obvious.

-

Weyfarer

Re: Making the TFF Aerial

I must say that backplate would make a dashed good coaster for one's brandy glass in the den.

Top hole old boy!

Top hole old boy!

- Loop Erimder

- Wild Carp

- Posts: 9984

- Joined: Wed Apr 04, 2012 11:33 pm

- 12

- Location: Leicestershire

Re: Making the TFF Aerial

Now that is a splendid idea :thumb: We know the master reel maker cannot fulfill the dreams of us all by making each and everyone of us a super reel, maybe the master can make a job lot off TFF brandy glass coastersWeyfarer wrote:I must say that backplate would make a dashed good coaster for one's brandy glass in the den.

Top hole old boy!

Chance is always powerful. Let your hook be always cast; in the pool where you least expect it, there will be a fish

- Beresford

- Sea Trout

- Posts: 4261

- Joined: Sat Dec 17, 2011 1:26 pm

- 12

Re: Making the TFF Aerial

Beautiful, craftsmanship. Eagerly awaiting the next stage. As always I'm in awe of your talent. It's topics like yours that help make this a fabulous forum.

The Split Cane Splinter Group

- MGs

- Pike

- Posts: 6423

- Joined: Wed Nov 02, 2011 2:24 pm

- 12

- Location: Cornwall

- Watermole+

- Chub

- Posts: 1057

- Joined: Thu Mar 15, 2012 11:07 pm

- 12

- Location: Devon & Cornwall border

Re: Making the TFF Aerial

Part 4. Making the Line Drum 1.

Anyway; the 'Coaster' has been shelved for the time being, as nothing more can be done to it until the starback and spindle have been made-and I don't want to do that until the line drum has been assembled, so here we go with the main feature of any reel..the spool, or Line drum.

As said last week, I have already bought a nice billet of top-grade, duralumin alloy. This is becoming a rather old-fashioned material now; the main difference to other aluminium alloys being that it 'age-hardens' i.e. It is fully machineable but after a few weeks of cutting, the metal becomes much tougher. I am not entirely sure why this phenomenon occurs..but I believe it was discovered by accident by a metallurgist.

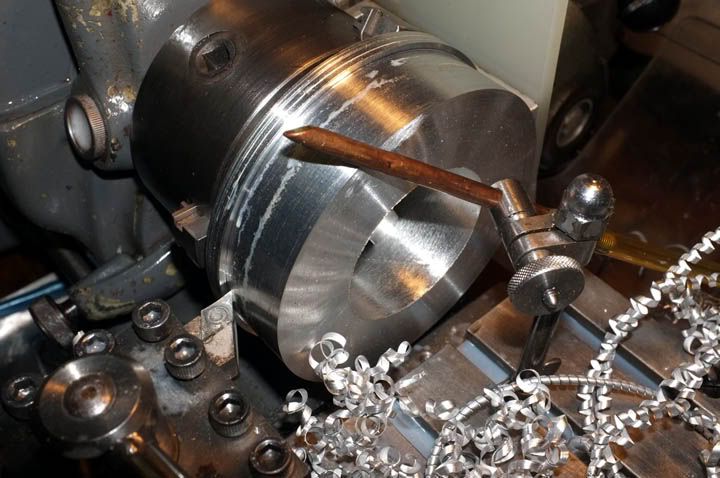

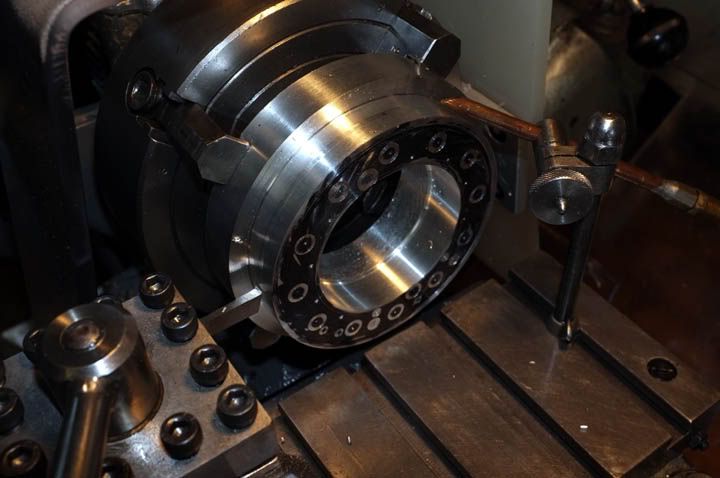

The only billet I could get reasonably cheaply, was an offcut of 5" diameter, which was far too big, so the first step was to roughly face off and then drill and bore a 2" hole through it. This could then be held in my lathe's 4-jaw chuck. The secret of concentric and true production of any component is to do as many of the machining operations as is possible, without removing the material from the chuck and I'm going to try and do just that, so that, when it is parted off, all that remains to be done is to just de-burr all the holes etc. and polish up.

This was then turned down to a bit more than 4 1/2" diameter, as I might make a bigger reel with the remaining, unused material one day and it seems a waste to turn away all of this fine metal to scrap.

Then it was bored to the internal finished size.

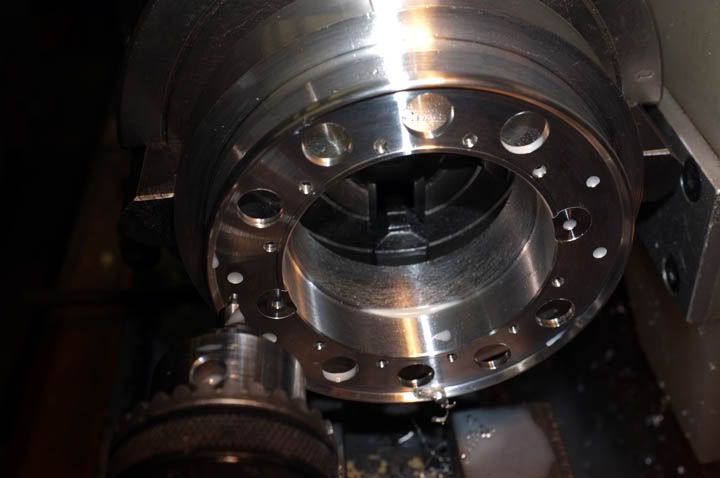

Now we come to the all-important holes-and there are a lot of them!

I decided that it would be better to create something original and not necessarily try to closely imitate an existing reel, although they all look very similar, generally speaking. A working drawing was produced on the workshop scrap pad and hopefully, the holes should all end up in the right places! It was back to basic maths and trig. for this; fortunately even an inexpensive modern calculator has trig. functions so calculation of hole positions was a doddle. Even so, it was prudent to test it first so I coloured the front with marker pen and lightly cut shallow marks to prove the drawing..

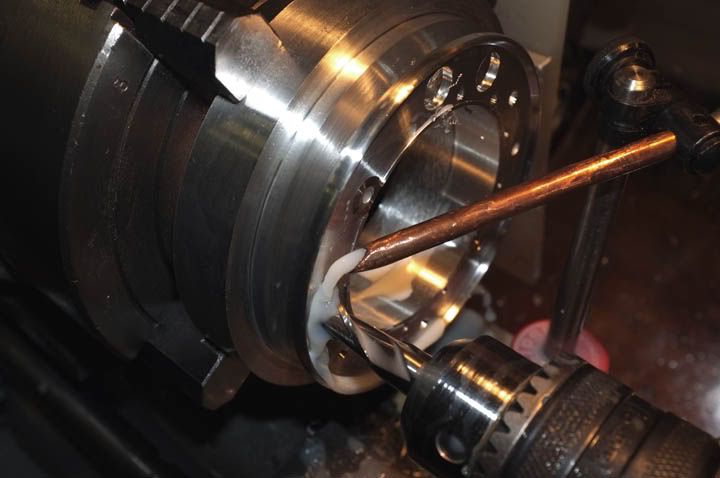

But before we started the hole cutting, it was necessary to undercut behind the front face to produce the plate thickness and also, to create the step for the spokes. A special deep undercut toll was made for this job..

Then the front face was finished accurately to drawing sizes and lightly polished. It will get scratched a good deal before machining operations are complete and need to be done again, so I wasn't too fussy about the finish.

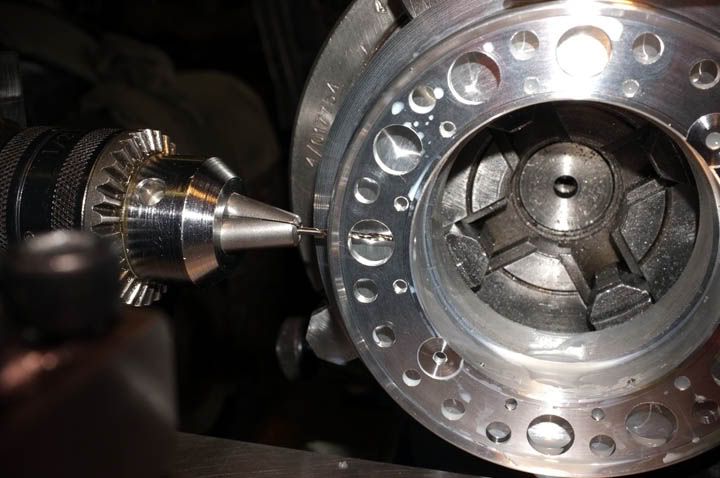

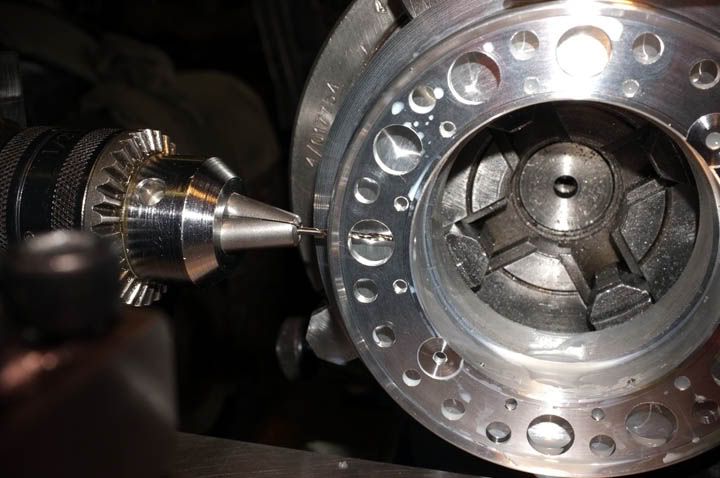

Everything seems OK so now it was time to set up my home-made drilling attachment, move it to the set positions and drill the 12 holes for the pillar screws. Everything from now on, both on outer-and inner plates, will now be orientated true and relative to these holes.

Having drilled all 12, we went around again and tapped the threads in them.

I thought about many different ways to screw the drum plates together, trying to work out a method whereby the screw heads would be visible from the front, but in the end, felt that it would be just too 'fussy' and unnecessarily complicate both construction and appearance.

The object is to make a nice 'clean' look to the front and have a line drum which can be dis-assembled if need be and so it will be held together in almost exactly the same way as the Coxon Project, i.e. by using machine screws through the pillars. If there is a weight issue, which is unlikely, I can drill out the centre cores of the screws to make them as hollow tubes.

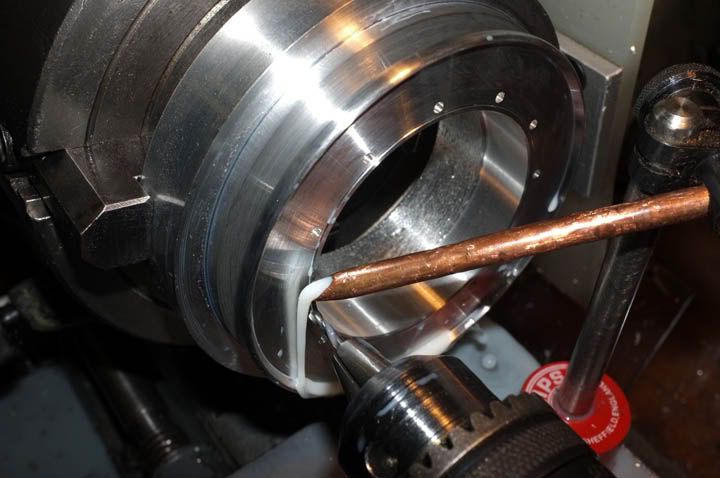

This will make a nice, simple appearance and at the same time, have an easily dis-assembled line drum. Here are the threads being cut:-

Now it was time put in both the flush-fitted,countersunk handle holes and the vent holes, large ones first. It was necessary to go very easy with the cutter in order not to distort the thin plate; orientation of hole position is vital here so frequent checking of the drawing was called for..

Next, the smaller, secondary vent holes were marked out by 'spot-drilling' first.

..and then drilling them out.

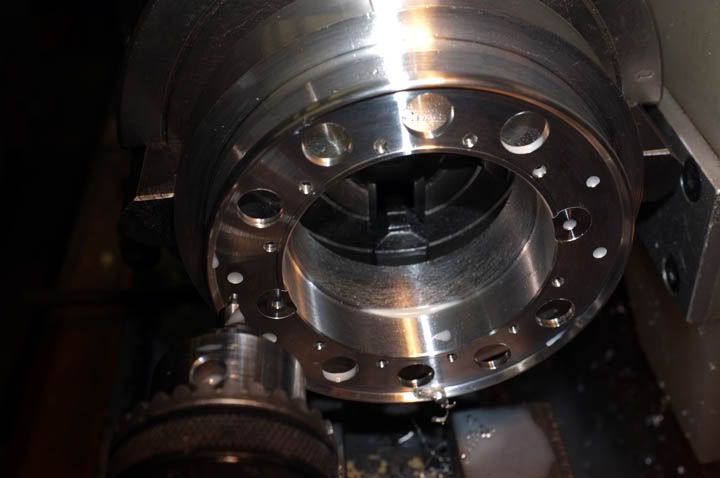

This completed the face-drilling ops. for the outer plate. Next, the attachment was set up in the adjacent position and clocked up true. Checking the orientation again before committing, the six, 1.6mm spoke holes were through-drilled..

...and then counter-drilled for the screw heads. I like them to be almost flush so there's no possibility of them catching line.

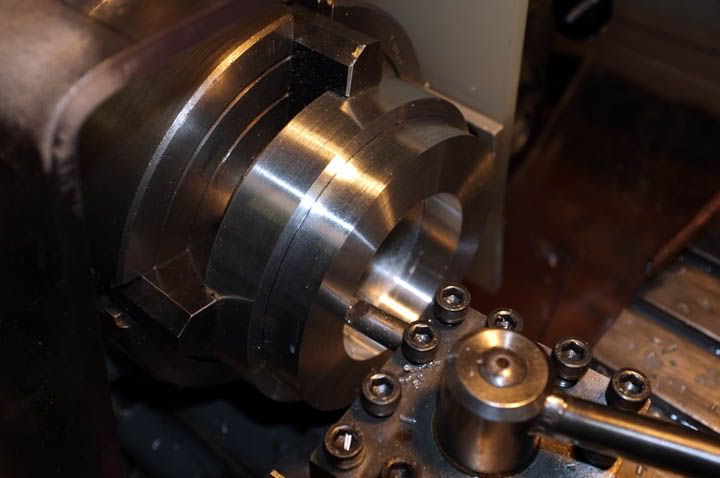

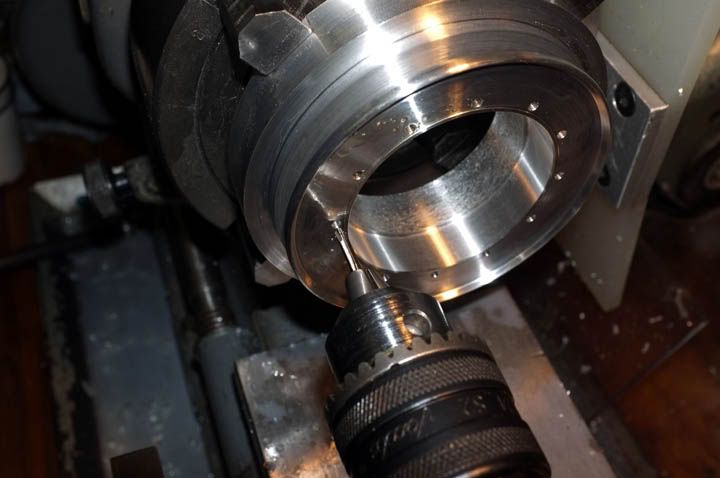

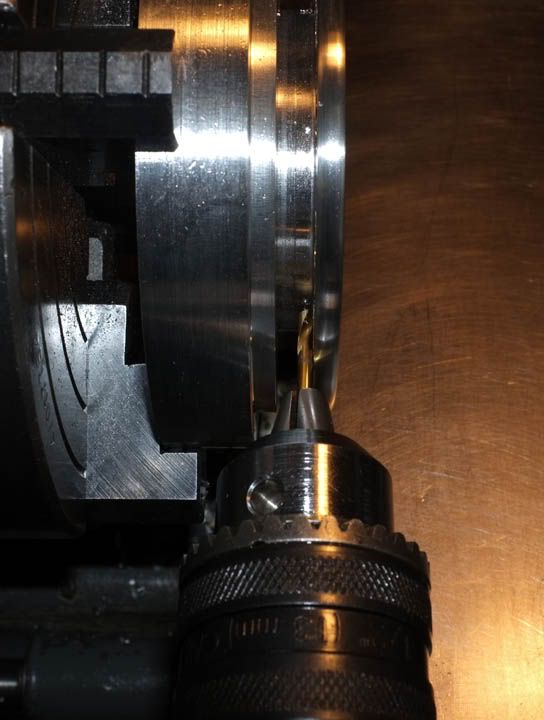

Now all that remains is to part off the plate to correct length. I ground up a very small, long-reach parting tool, just for this job..it worked fine!

It just needs de-burring and we can start on the inner plate..

..more next week.

With regards,

wm+

P.S. The Perfection Roach is coming along fine..has all been glued up and 'in the string' but I don't expect to finish it for a few months yet though..This reel will be it's companion when finished.

..Now That Gentlemen, is a Capital idea! :thumb: ..not now, but perhaps maybe we might be able to do something in the future..Many thanks to you both for the suggestion!Loop Erimder wrote:Now that is a splendid idea :thumb: We know the master reel maker cannot fulfill the dreams of us all by making each and everyone of us a super reel, maybe the master can make a job lot off TFF brandy glass coastersWeyfarer wrote:I must say that backplate would make a dashed good coaster for one's brandy glass in the den.

Top hole old boy!(just kidding watermole+)

Anyway; the 'Coaster' has been shelved for the time being, as nothing more can be done to it until the starback and spindle have been made-and I don't want to do that until the line drum has been assembled, so here we go with the main feature of any reel..the spool, or Line drum.

As said last week, I have already bought a nice billet of top-grade, duralumin alloy. This is becoming a rather old-fashioned material now; the main difference to other aluminium alloys being that it 'age-hardens' i.e. It is fully machineable but after a few weeks of cutting, the metal becomes much tougher. I am not entirely sure why this phenomenon occurs..but I believe it was discovered by accident by a metallurgist.

The only billet I could get reasonably cheaply, was an offcut of 5" diameter, which was far too big, so the first step was to roughly face off and then drill and bore a 2" hole through it. This could then be held in my lathe's 4-jaw chuck. The secret of concentric and true production of any component is to do as many of the machining operations as is possible, without removing the material from the chuck and I'm going to try and do just that, so that, when it is parted off, all that remains to be done is to just de-burr all the holes etc. and polish up.

This was then turned down to a bit more than 4 1/2" diameter, as I might make a bigger reel with the remaining, unused material one day and it seems a waste to turn away all of this fine metal to scrap.

Then it was bored to the internal finished size.

Now we come to the all-important holes-and there are a lot of them!

I decided that it would be better to create something original and not necessarily try to closely imitate an existing reel, although they all look very similar, generally speaking. A working drawing was produced on the workshop scrap pad and hopefully, the holes should all end up in the right places! It was back to basic maths and trig. for this; fortunately even an inexpensive modern calculator has trig. functions so calculation of hole positions was a doddle. Even so, it was prudent to test it first so I coloured the front with marker pen and lightly cut shallow marks to prove the drawing..

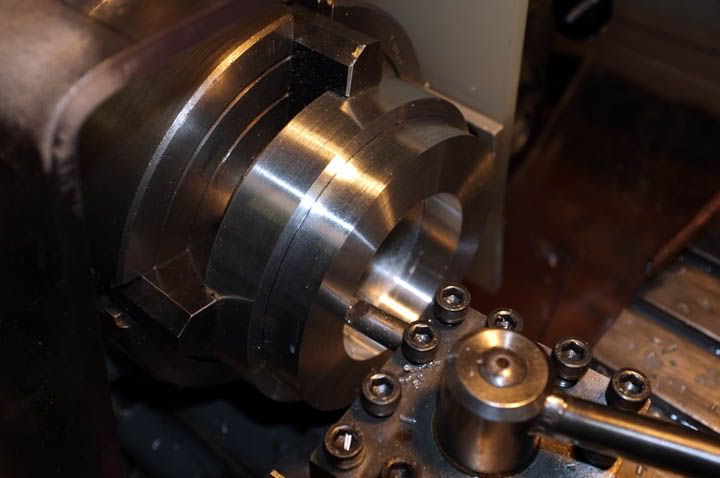

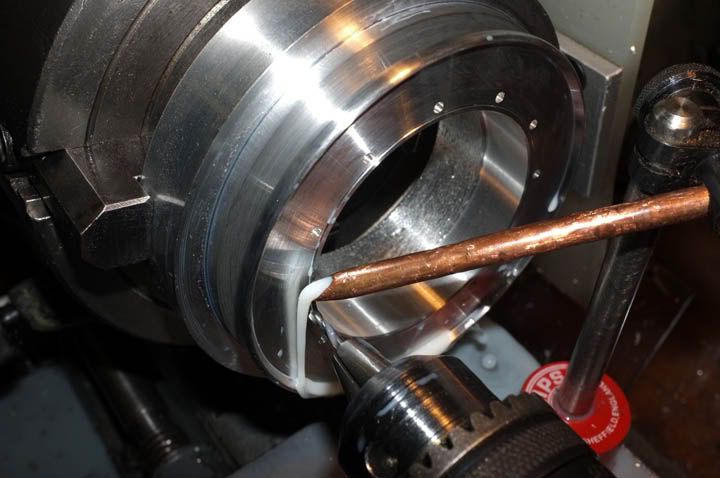

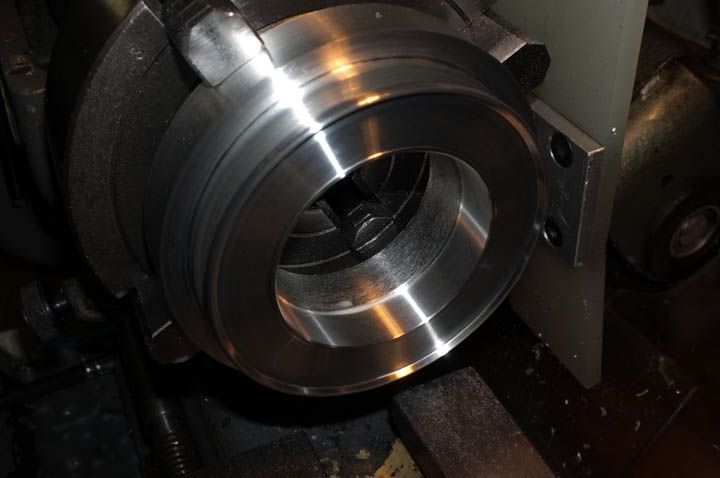

But before we started the hole cutting, it was necessary to undercut behind the front face to produce the plate thickness and also, to create the step for the spokes. A special deep undercut toll was made for this job..

Then the front face was finished accurately to drawing sizes and lightly polished. It will get scratched a good deal before machining operations are complete and need to be done again, so I wasn't too fussy about the finish.

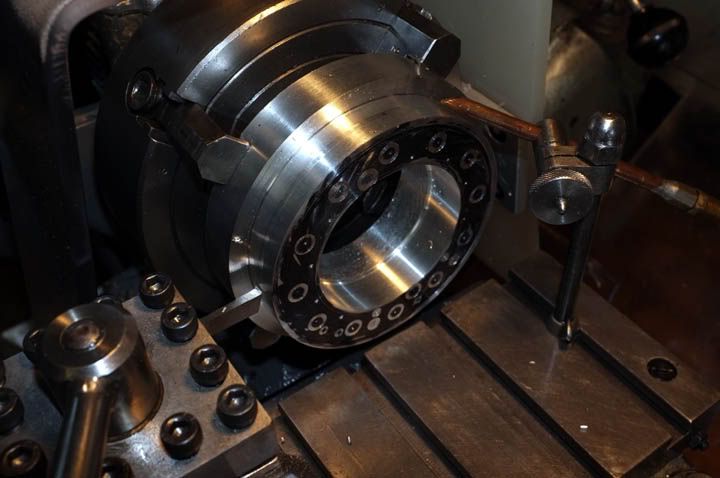

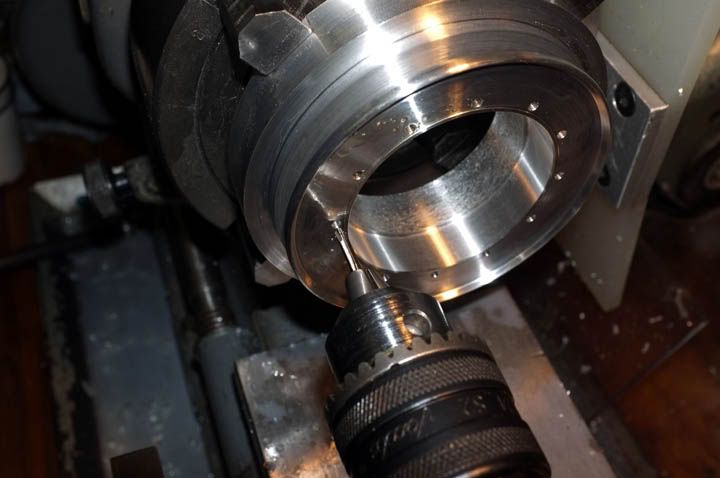

Everything seems OK so now it was time to set up my home-made drilling attachment, move it to the set positions and drill the 12 holes for the pillar screws. Everything from now on, both on outer-and inner plates, will now be orientated true and relative to these holes.

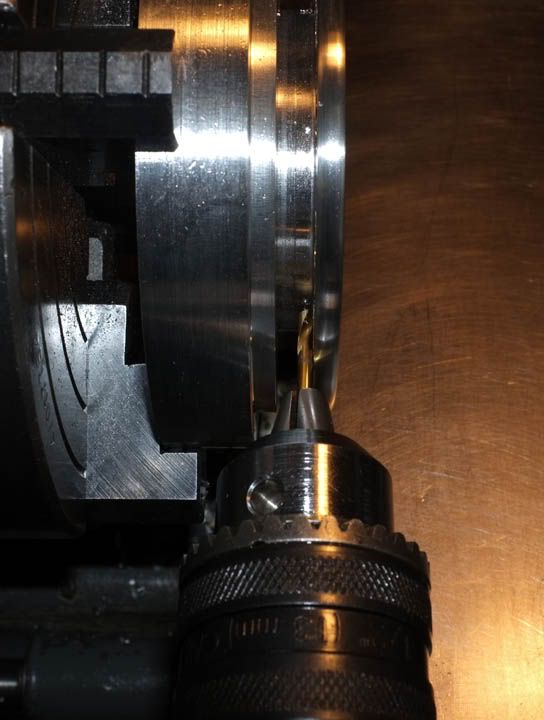

Having drilled all 12, we went around again and tapped the threads in them.

I thought about many different ways to screw the drum plates together, trying to work out a method whereby the screw heads would be visible from the front, but in the end, felt that it would be just too 'fussy' and unnecessarily complicate both construction and appearance.

The object is to make a nice 'clean' look to the front and have a line drum which can be dis-assembled if need be and so it will be held together in almost exactly the same way as the Coxon Project, i.e. by using machine screws through the pillars. If there is a weight issue, which is unlikely, I can drill out the centre cores of the screws to make them as hollow tubes.

This will make a nice, simple appearance and at the same time, have an easily dis-assembled line drum. Here are the threads being cut:-

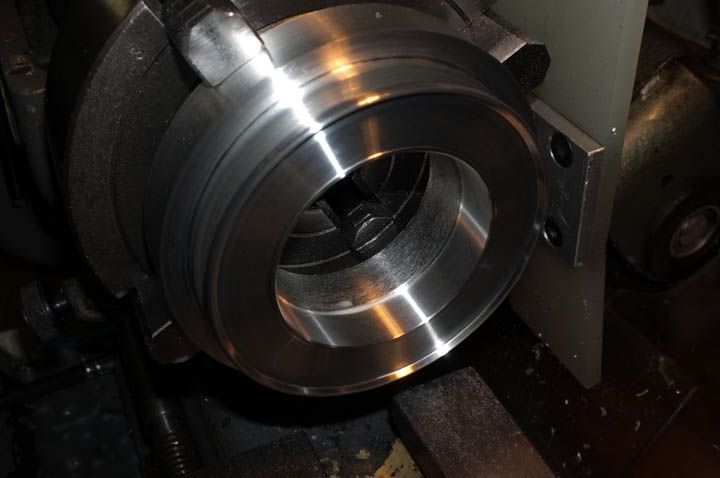

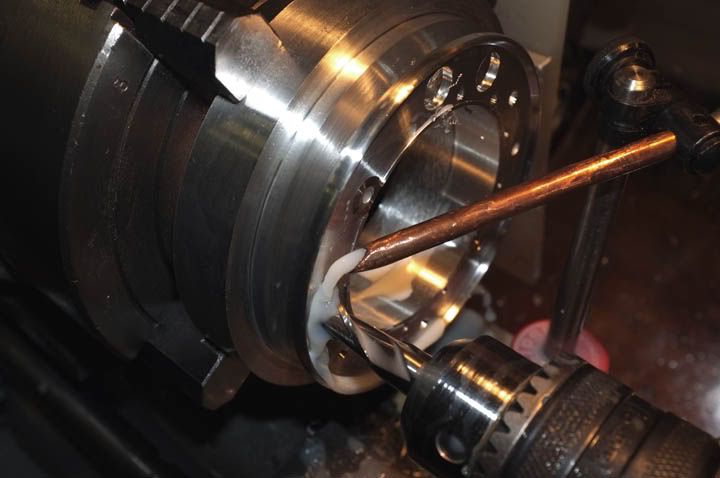

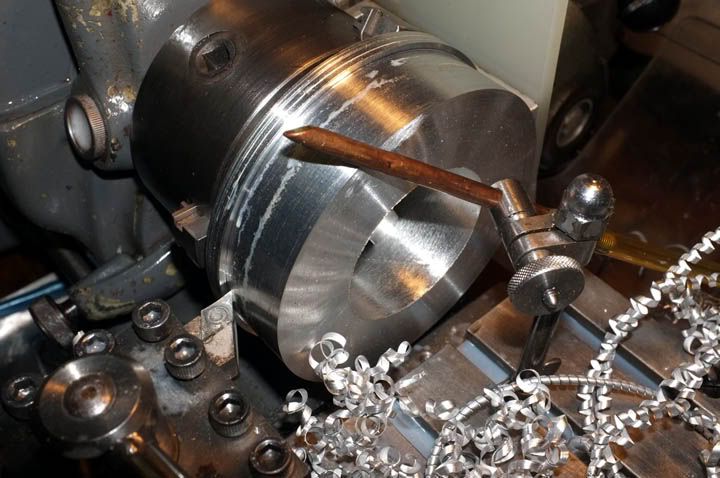

Now it was time put in both the flush-fitted,countersunk handle holes and the vent holes, large ones first. It was necessary to go very easy with the cutter in order not to distort the thin plate; orientation of hole position is vital here so frequent checking of the drawing was called for..

Next, the smaller, secondary vent holes were marked out by 'spot-drilling' first.

..and then drilling them out.

This completed the face-drilling ops. for the outer plate. Next, the attachment was set up in the adjacent position and clocked up true. Checking the orientation again before committing, the six, 1.6mm spoke holes were through-drilled..

...and then counter-drilled for the screw heads. I like them to be almost flush so there's no possibility of them catching line.

Now all that remains is to part off the plate to correct length. I ground up a very small, long-reach parting tool, just for this job..it worked fine!

It just needs de-burring and we can start on the inner plate..

..more next week.

With regards,

wm+

P.S. The Perfection Roach is coming along fine..has all been glued up and 'in the string' but I don't expect to finish it for a few months yet though..This reel will be it's companion when finished.

Last edited by Watermole+ on Sun Aug 05, 2012 8:38 am, edited 1 time in total.

"Are not two sparrows sold for a farthing? Yet one of them shall not fall without your Father knoweth" ..Jesus of Nazareth, King James AV

- Beresford

- Sea Trout

- Posts: 4261

- Joined: Sat Dec 17, 2011 1:26 pm

- 12

Re: Making the TFF Aerial

I'm rapidly running out of superlatives every time I visit your workbench. What can I say?

The Split Cane Splinter Group

- Mark

- Head Bailiff

- Posts: 21193

- Joined: Mon Aug 22, 2011 4:55 pm

- 12

- Location: Leicestershire

- Contact:

Re: Making the TFF Aerial

Lovely wm+. :thumb:

Mark (Administrator)

The most precious places in the English landscape are those secretive corners,

where you find only elder trees, nettles and dreams. (BB - Denys Watkins-Pitchford).

The most precious places in the English landscape are those secretive corners,

where you find only elder trees, nettles and dreams. (BB - Denys Watkins-Pitchford).