Making the TFF Aerial

- Loop Erimder

- Wild Carp

- Posts: 9984

- Joined: Wed Apr 04, 2012 11:33 pm

- 12

- Location: Leicestershire

Re: Making the TFF Aerial

Very good that, keep em coming :thumb:

Chance is always powerful. Let your hook be always cast; in the pool where you least expect it, there will be a fish

- Watermole+

- Chub

- Posts: 1057

- Joined: Thu Mar 15, 2012 11:07 pm

- 12

- Location: Devon & Cornwall border

Re: Making the TFF Aerial

Part 5. Making the Line Drum 2.

..Have not had opportunity to make much progress this week as have been rather involved with a repair and maintenance project on a local river bridge. It's actually rather an honour to be part of the team doing this work and although it won't be finished for several months yet, it's coming along quite nicely and what we are doing should last for a good few years yet!

Anyway, as regards the TFF Aerial, I've managed to complete the inner plate and the next step will be to make the spacers, or pillars, which hold the two together. Drawing on the experience gained, making the Coxon, much greater accuracy has been achieved and this one should be much more finely finished as a result. I've also improved on the method of indexing the lathe chuck for producing the holes so all-in-all, work is progressing rather well, albeit slowly..if that's not a contradiction in terms!

So, making the inner plate for the line drum..

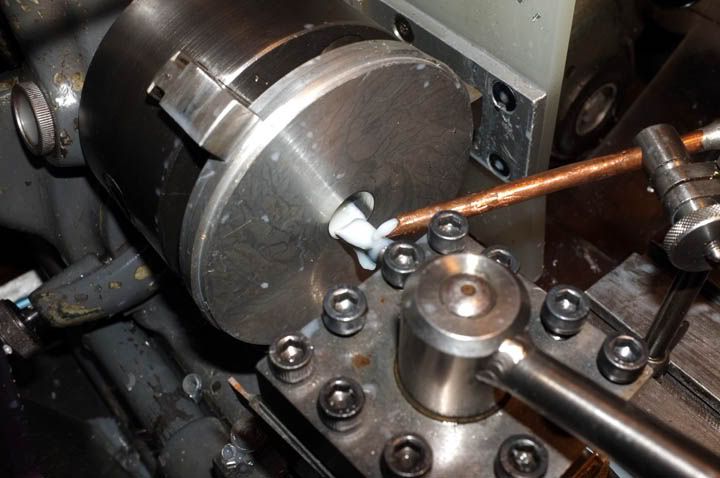

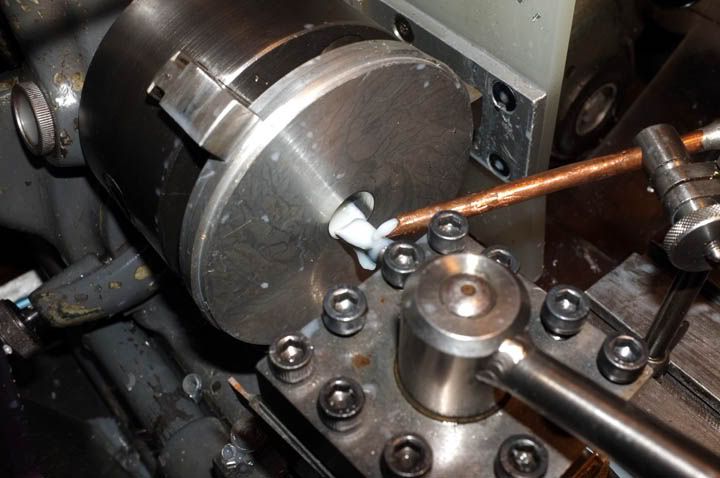

I started by putting a billet of the same grade of duralumin in the chuck, drilling a pilot hole and then boring out to size, minus 0.050"..

..which was then roughly turned. It's always best to get rid of all excess material before finishing.

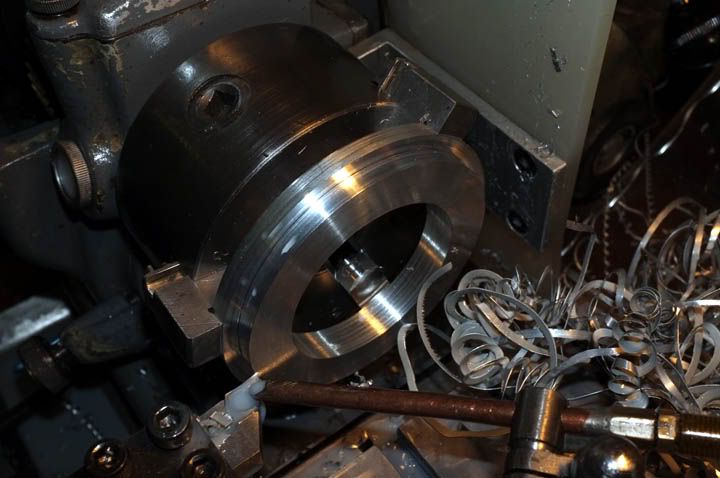

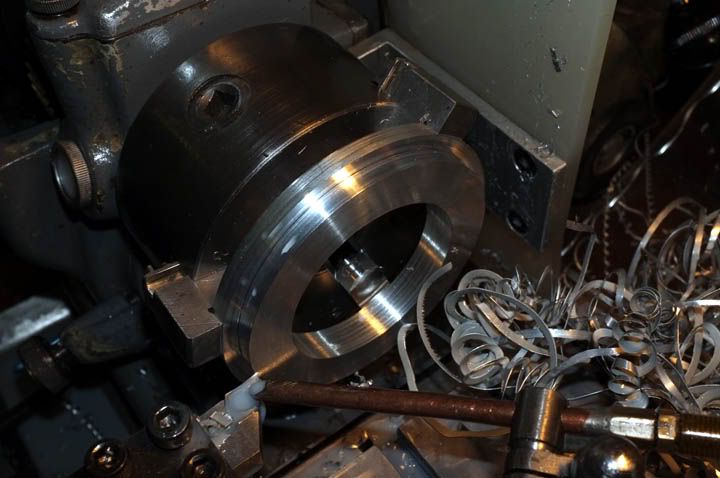

Then, it was finish-turned to size and the step produced for the spokes.

Next, we set up the drilling attachment and spot-drilled the holes for the pillars..

..before through-drilling.

Then the vent holes were slot-drilled in..

..and the spoke holes.

Next, the plate was reversed in the chuck, clocked up true and turned to final thickness..

..then counter-bored out.

Here you see both plates complete.

The twelve pillar holes have been through-drilled and countersunk to accept the joining screws, yet to be made..

More, -as soon as I can get to it... ...bridge repair work permitting!!

Regards from wm+

..Have not had opportunity to make much progress this week as have been rather involved with a repair and maintenance project on a local river bridge. It's actually rather an honour to be part of the team doing this work and although it won't be finished for several months yet, it's coming along quite nicely and what we are doing should last for a good few years yet!

Anyway, as regards the TFF Aerial, I've managed to complete the inner plate and the next step will be to make the spacers, or pillars, which hold the two together. Drawing on the experience gained, making the Coxon, much greater accuracy has been achieved and this one should be much more finely finished as a result. I've also improved on the method of indexing the lathe chuck for producing the holes so all-in-all, work is progressing rather well, albeit slowly..if that's not a contradiction in terms!

So, making the inner plate for the line drum..

I started by putting a billet of the same grade of duralumin in the chuck, drilling a pilot hole and then boring out to size, minus 0.050"..

..which was then roughly turned. It's always best to get rid of all excess material before finishing.

Then, it was finish-turned to size and the step produced for the spokes.

Next, we set up the drilling attachment and spot-drilled the holes for the pillars..

..before through-drilling.

Then the vent holes were slot-drilled in..

..and the spoke holes.

Next, the plate was reversed in the chuck, clocked up true and turned to final thickness..

..then counter-bored out.

Here you see both plates complete.

The twelve pillar holes have been through-drilled and countersunk to accept the joining screws, yet to be made..

More, -as soon as I can get to it... ...bridge repair work permitting!!

Regards from wm+

Last edited by Watermole+ on Sun Aug 05, 2012 8:44 am, edited 2 times in total.

"Are not two sparrows sold for a farthing? Yet one of them shall not fall without your Father knoweth" ..Jesus of Nazareth, King James AV

- Loop Erimder

- Wild Carp

- Posts: 9984

- Joined: Wed Apr 04, 2012 11:33 pm

- 12

- Location: Leicestershire

Re: Making the TFF Aerial

Never a dull stage in this project lovely wm+

Chance is always powerful. Let your hook be always cast; in the pool where you least expect it, there will be a fish

- Mark

- Head Bailiff

- Posts: 21193

- Joined: Mon Aug 22, 2011 4:55 pm

- 12

- Location: Leicestershire

- Contact:

Re: Making the TFF Aerial

Yes, very intriguing as usual. :thumb:

Mark (Administrator)

The most precious places in the English landscape are those secretive corners,

where you find only elder trees, nettles and dreams. (BB - Denys Watkins-Pitchford).

The most precious places in the English landscape are those secretive corners,

where you find only elder trees, nettles and dreams. (BB - Denys Watkins-Pitchford).

- LuckyLuca

- Barbel

- Posts: 4792

- Joined: Mon Jul 02, 2012 10:20 am

- 11

- Location: Oxfordshire

Re: Making the TFF Aerial

Fascinating! I so look forward to every installment. Thank you again for sharing this with us wm+

I walked across an empty land

I knew the pathway like the back of my hand

I felt the earth beneath my feet

Sat by the river and it made me complete.

I knew the pathway like the back of my hand

I felt the earth beneath my feet

Sat by the river and it made me complete.

- Watermole+

- Chub

- Posts: 1057

- Joined: Thu Mar 15, 2012 11:07 pm

- 12

- Location: Devon & Cornwall border

Re: Making the TFF Aerial

Part 6. Completing the line drum

The two side plates for the line drum have now been all but finished and only need some minor adjustments and polishing; this will be done before final assembly.

However, we firstly need to make the pillars, or spacers, to join them together-and of course, the twelve screws, two of which will be for the handles. I decided that the method used for this when making the Coxon project was fine and so, with one-or two small improvements, didn't see any reason to deviate from it. There are no rivets, the drum can be completely dis-assembled if required and complete accuracy was maintained when re-assembling so why change it for the sake of change?

For making the pillars, I used some of the same, drawn nickel-ali. bronze tubing which I use for rod ferrule making. However, it is vital that they are all cut to identical length, otherwise severe problems with true running will certainly result. The first time I did this, it was a bit of a painful process, constantly re-facing off before they were all the same, but this time, lessons were learnt and it was relatively simple to do, before I achieved a result and all were identical to within 0.0006". (just over 1/2 of 1/1000")

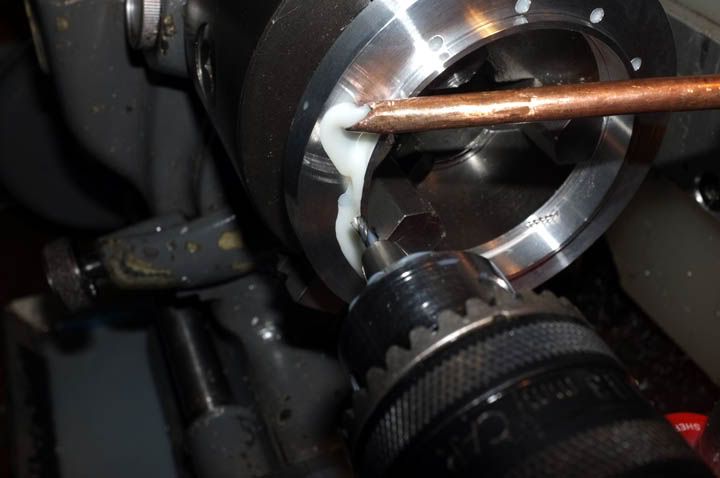

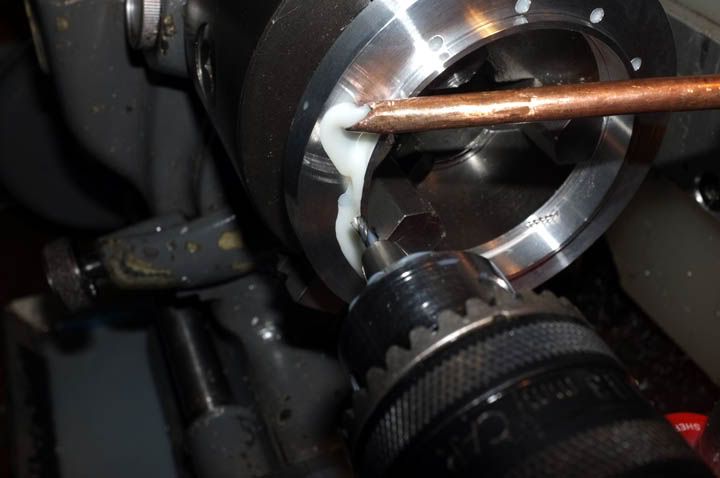

To turn them, I made an interference fit, small tapered arbor for the headstock end and supported the other end with a running centre..

..taking a series of small cuts, using the same radius tool which I ground up for the Coxon pillars. By turning from an arbor, complete concentricity was assured and then it was just a matter of buffing out the turning tool marks and giving them a good polish to harden the metal surface to prevent corrosion. The centre diameter where the line goes is 5/32" (0.1562") and I turned the flaring on the ends to give good location support on the plate faces. They give the impression of being rather heavy but I can assure you that they have a wall thickness of only 0.0157" and are in fact, extremely light!

As before, I made the screws from standard M3 countersunk stainless ones, and extensively modified them by reducing the head diameter to 0.156" and re-cutting the 45 degree back faces to make very small heads which would locate precisely centrally in the inner plate holes.

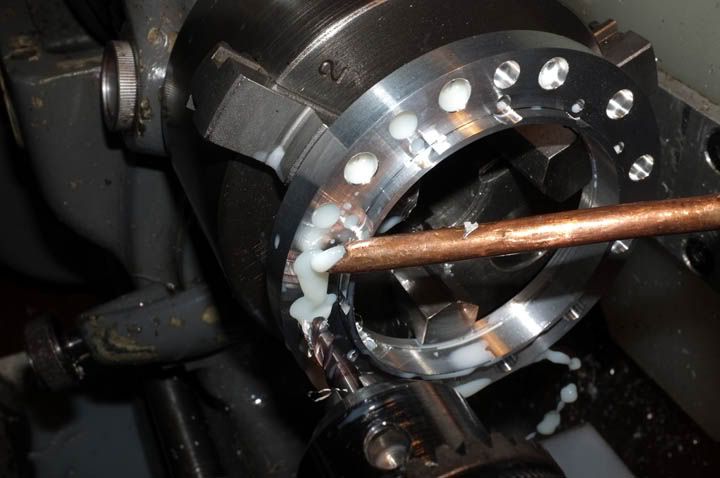

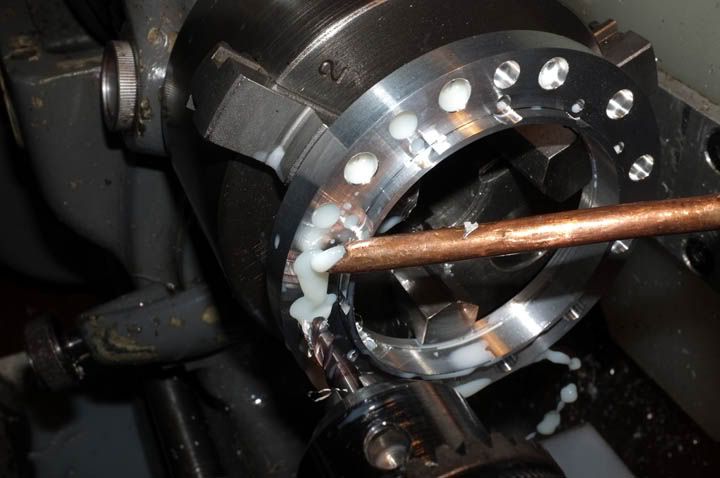

It was then time for a trial assembly, to make sure everything fits and the side plates are dead parallel to each other. All the screws were first located and then gradually tightened in opposite pairs to minimize the chance of distortion. The holes where the handles will go are threaded at the moment, but will be clearance-drilled when the handles are ready to go on.

This is the inner face. You can see how the fixing screws are now flush with the surface.

Next time, we be making the all-important line drum hub and the reel spindle..

With regards,

wm+

The two side plates for the line drum have now been all but finished and only need some minor adjustments and polishing; this will be done before final assembly.

However, we firstly need to make the pillars, or spacers, to join them together-and of course, the twelve screws, two of which will be for the handles. I decided that the method used for this when making the Coxon project was fine and so, with one-or two small improvements, didn't see any reason to deviate from it. There are no rivets, the drum can be completely dis-assembled if required and complete accuracy was maintained when re-assembling so why change it for the sake of change?

For making the pillars, I used some of the same, drawn nickel-ali. bronze tubing which I use for rod ferrule making. However, it is vital that they are all cut to identical length, otherwise severe problems with true running will certainly result. The first time I did this, it was a bit of a painful process, constantly re-facing off before they were all the same, but this time, lessons were learnt and it was relatively simple to do, before I achieved a result and all were identical to within 0.0006". (just over 1/2 of 1/1000")

To turn them, I made an interference fit, small tapered arbor for the headstock end and supported the other end with a running centre..

..taking a series of small cuts, using the same radius tool which I ground up for the Coxon pillars. By turning from an arbor, complete concentricity was assured and then it was just a matter of buffing out the turning tool marks and giving them a good polish to harden the metal surface to prevent corrosion. The centre diameter where the line goes is 5/32" (0.1562") and I turned the flaring on the ends to give good location support on the plate faces. They give the impression of being rather heavy but I can assure you that they have a wall thickness of only 0.0157" and are in fact, extremely light!

As before, I made the screws from standard M3 countersunk stainless ones, and extensively modified them by reducing the head diameter to 0.156" and re-cutting the 45 degree back faces to make very small heads which would locate precisely centrally in the inner plate holes.

It was then time for a trial assembly, to make sure everything fits and the side plates are dead parallel to each other. All the screws were first located and then gradually tightened in opposite pairs to minimize the chance of distortion. The holes where the handles will go are threaded at the moment, but will be clearance-drilled when the handles are ready to go on.

This is the inner face. You can see how the fixing screws are now flush with the surface.

Next time, we be making the all-important line drum hub and the reel spindle..

With regards,

wm+

"Are not two sparrows sold for a farthing? Yet one of them shall not fall without your Father knoweth" ..Jesus of Nazareth, King James AV

- Loop Erimder

- Wild Carp

- Posts: 9984

- Joined: Wed Apr 04, 2012 11:33 pm

- 12

- Location: Leicestershire

Re: Making the TFF Aerial

Brillyunt! .......if only I had the skills and patience :think: :thumb:

Chance is always powerful. Let your hook be always cast; in the pool where you least expect it, there will be a fish

- Mark

- Head Bailiff

- Posts: 21193

- Joined: Mon Aug 22, 2011 4:55 pm

- 12

- Location: Leicestershire

- Contact:

Re: Making the TFF Aerial

It's starting to take shape, very nice wm+, very nice indeed. :thumb:

Mark (Administrator)

The most precious places in the English landscape are those secretive corners,

where you find only elder trees, nettles and dreams. (BB - Denys Watkins-Pitchford).

The most precious places in the English landscape are those secretive corners,

where you find only elder trees, nettles and dreams. (BB - Denys Watkins-Pitchford).

- Nobby

- Wild Carp

- Posts: 10987

- Joined: Sun Oct 02, 2011 2:40 pm

- 12

- Location: S.W.Surrey

- Contact:

Re: Making the TFF Aerial

Lovely!

I doubt you could make that reel any lighter and with so many pillars it shouldn't 'dink' the line.

I can't wait for the next instalment.

I doubt you could make that reel any lighter and with so many pillars it shouldn't 'dink' the line.

I can't wait for the next instalment.

- MGs

- Pike

- Posts: 6423

- Joined: Wed Nov 02, 2011 2:24 pm

- 12

- Location: Cornwall

Re: Making the TFF Aerial

Lovely work as usual :hat:

Old car owners never die....they just rust away